The Art of Industrial Pattern Making at Proline Barcelona

Industrial pattern making is a fundamental technique in the textile industry that allows creative designs to be transformed into high-quality tangible products. At Proline Barcelona, we specialize in creating precise and efficient patterns that optimize the production process and ensure a perfect fit for each garment.

What is Industrial Pattern Making?

Industrial pattern making refers to the process of creating patterns on a large scale for mass garment production. Unlike manual pattern making, which is done by hand and is more suitable for small or customized productions, industrial pattern making uses advanced tools and software to design and adjust patterns with millimeter precision.

History of Industrial Pattern Making

The development of industrial pattern making began with the Industrial Revolution in the 18th century, when mass production became a necessity. With the invention of sewing machines and other textile equipment, there was a need to create patterns that could be consistently and efficiently replicated.

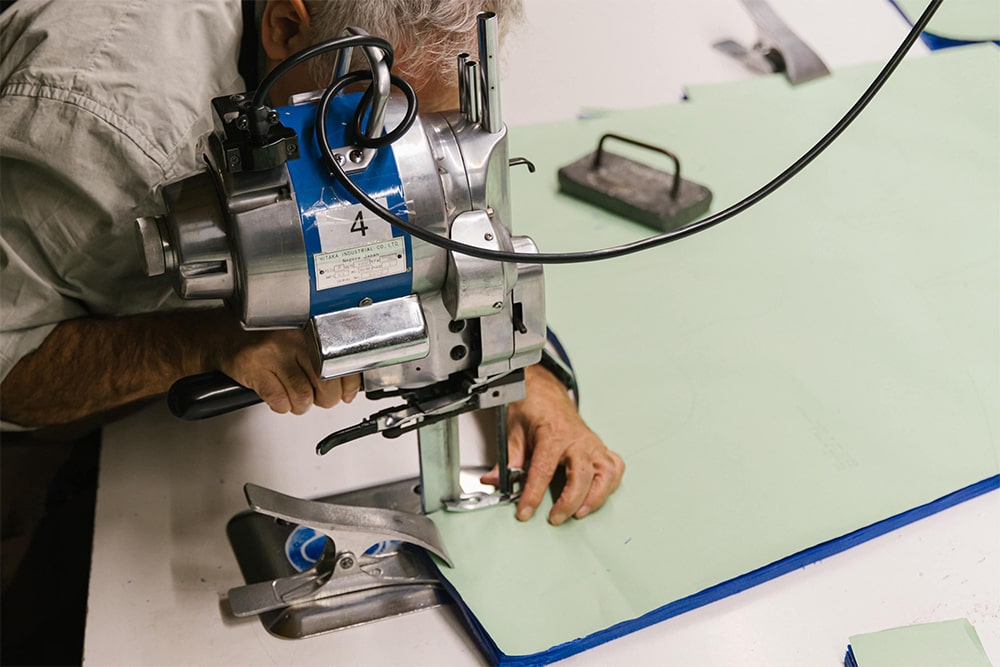

Tools and Technology

Today, industrial pattern making relies on advanced technologies such as CAD (Computer-Aided Design) software. These tools allow designers to create, modify, and adjust patterns digitally, improving accuracy and reducing production time.

Advantages of Industrial Pattern Making

· Efficiency and Consistency: By using specialized software, patterns can be created that are replicated with accuracy, ensuring that each garment is identical to the previous one.

· Cost Reduction: Automating the pattern-making process reduces the time and costs associated with manual production.

· Adaptability: Industrial patterns can be easily adjusted and modified for different sizes and styles, allowing for greater flexibility in production.

· Sustainability: By optimizing material usage and minimizing waste, industrial pattern making contributes to more sustainable practices in the textile industry.

· Cost Reduction: Automating the pattern-making process reduces the time and costs associated with manual production.

· Adaptability: Industrial patterns can be easily adjusted and modified for different sizes and styles, allowing for greater flexibility in production.

· Sustainability: By optimizing material usage and minimizing waste, industrial pattern making contributes to more sustainable practices in the textile industry.

The Process at Proline Barcelona

At Proline Barcelona, we combine over 30 years of experience with cutting-edge technology to offer industrial pattern-making solutions that meet the highest quality standards. Our team of designers and technicians works closely together to develop patterns that are not only functional but also innovative and aesthetically appealing.

Applications of Industrial Pattern Making

Industrial pattern making is used in a wide range of applications, from high-fashion couture to sportswear and uniforms. Each type of garment requires a specific approach to ensure that the final design is comfortable, functional, and aesthetically pleasing.

The Future of Industrial Pattern Making

With the continuous advancement of technology, the future of industrial pattern making promises to be even more innovative. The integration of artificial intelligence and 3D printing is opening new possibilities for customization and efficiency in garment production.