Laser Technology in the Textile Industry

Laser technology is revolutionizing the textile industry by offering sustainable and efficient solutions. At Proline Barcelona, we have integrated this technology into several of our processes.

Beginnings

Laser technology was introduced to the textile industry by the company Jeanologia in the 1990s. This innovation increased worker safety, efficiency, and sustainability in production. By the 2000s, laser technology was incorporated into many more processes, achieving results that were impossible to obtain using traditional methods.

Applications and Advantages of Laser Technology

Laser Cutting and Engraving of Textiles

Laser cutting allows for precise, contact-free cuts, preventing material deformation and ensuring clean, fray-free edges. This is especially useful for synthetic materials, as the laser can seal the edges while cutting, leaving them perfect.

Laser Washing

Laser washing is a technique that uses highly focused light beams to selectively remove color from fabric, creating worn and distressed effects. This method is much more environmentally friendly than traditional processes, as it significantly reduces the use of water and chemicals.

Customization and On-Demand Production

Laser technology allows for high product customization, making it ideal for on-demand production. This not only reduces overproduction and waste, but also enables companies to offer unique, personalized products to their customers.

Sustainability

The use of lasers in the textile industry contributes to sustainability by reducing water and chemical consumption. For example, in jeans manufacturing, laser technology can cut water usage by up to 64% compared to traditional methods.

Innovation in Designs

The precision of lasers allows for the creation of complex and detailed designs that would be difficult to achieve with traditional methods. This opens up new creative possibilities for designers and enables the production of innovative, high-quality garments.

Efficiency and Productivity

Laser systems are fast and efficient, which increases production capacity. For example, some systems can process more than 4,000 units per day, making them ideal for meeting the demands of fast fashion without compromising quality. The precision of the laser allows for the creation of complex and detailed designs that would be difficult to achieve with traditional methods. This opens up new creative possibilities for designers and enables the production of innovative, high-quality garments.

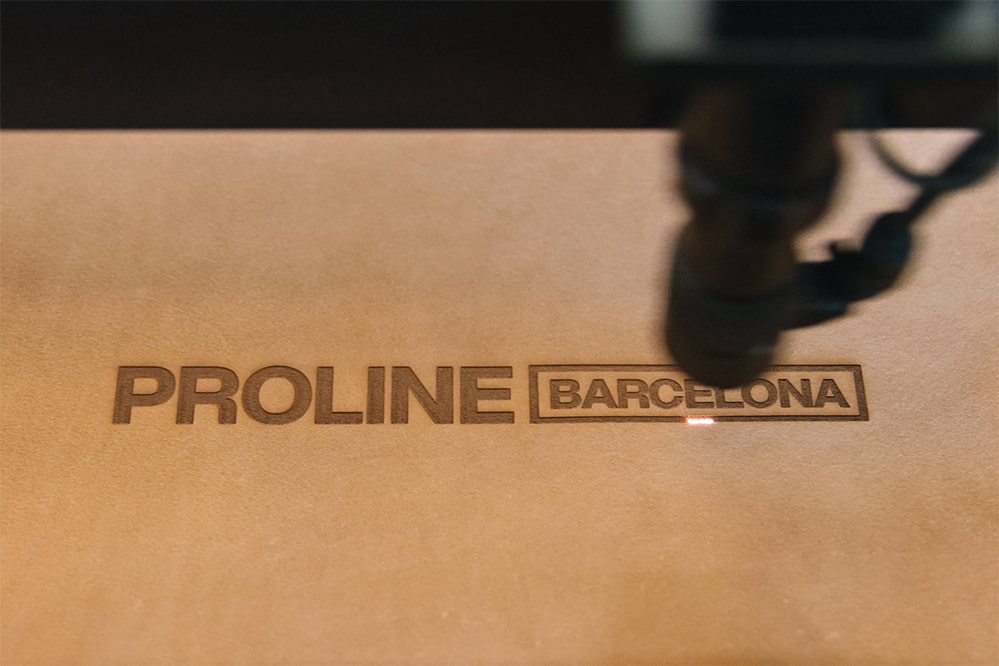

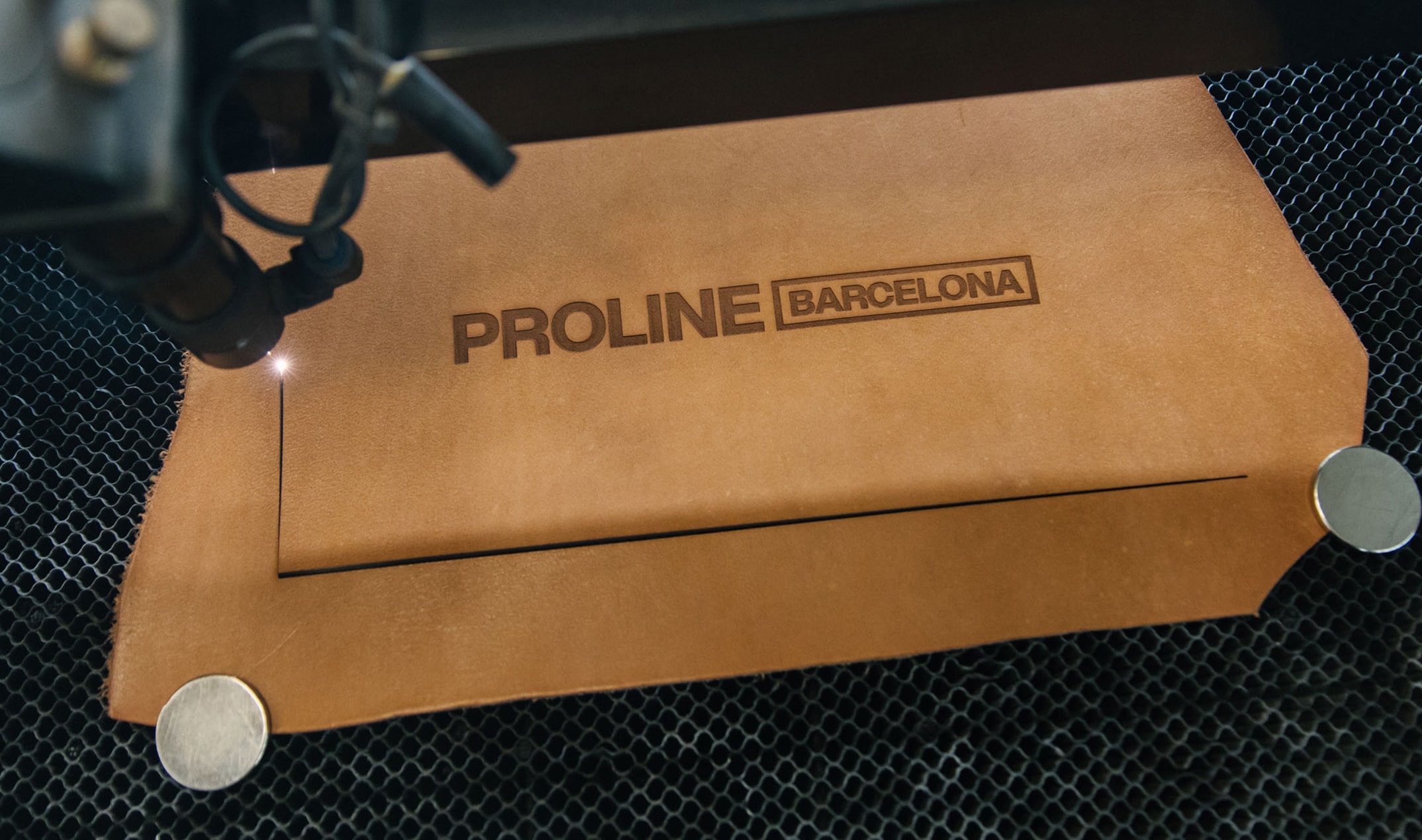

Use at Proline Barcelona

At Proline Barcelona, we use a CO2 laser cutter, which allows us to make precise cuts in a variety of materials. Our expertise extends to cutting woven and nonwoven fabrics, thin foams, plastics, and both synthetic and natural leather, as well as all types of polyamide and polyester fabrics. By using our laser cutter in engraving mode, we can create captivating visual effects or brand logos on our clients' products. This versatile technology is applicable to a wide range of fabrics and materials.